COLORADO SPRINGS — A new company has shown its intentions to create inflatable modules that it believes can be larger and cheaper than other options, to support commercial space stations and other uses.

Max Space is creating a series of expandable modules, with the first one set to launch on a SpaceX rideshare mission in 2025. The initial Max Space 20 module, compressed into a two-cubic-meter volume for launch, will expand to 20 cubic meters after deployment, becoming the largest expandable module flown so far.

Aaron Kemmer, co-founder and CEO of Max Space, explained in an interview that his interest in expandable modules came from his experience at space manufacturing company Made In Space, known for producing 3-D printers used on the International Space Station.

“Whenever we tried to do something significant, we always encountered a volume bottleneck,” he said, giving an example of fitting a system to produce high-quality optical fiber that, on Earth, would occupy three stories, into a standard ISS locker. “The most challenging part wasn't making it work in space. The most challenging part was actually making it work within a limited volume.”

The concept of expandable modules is not new. The former Bigelow Aerospace had plans that heavily involved this technology, which led to the launch of the Genesis 1 and 2 spacecraft and the construction of the Bigelow Expandable Activity Module (BEAM) currently on the ISS. More recently, companies like Lockheed Martin and Sierra Space have tested inflatable modules on the ground, but haven't yet flown them.

Max Space is taking a different technical approach compared to previous systems that used a bi-directional “basket weave” fabric structure. Maxim de Jong, co-founder and chief technology officer of Max Space, explained that using fibers going in two different directions makes it difficult to determine the load in each direction.

This necessitates extra material for safety margins and makes it challenging to scale up designs for larger volumes. “Every scale-up is a specific design and must be revalidated,” he said.

Max Space is pursuing a technology called an ultra-high-performance vessel created by de Jong, which distributes loads in one direction. This reduces the uncertainty in safety margins, as demonstrated in tests where modules burst at pressures within 10% of the predicted levels. “The predictability is excellent, and the scalability is great,” he said.

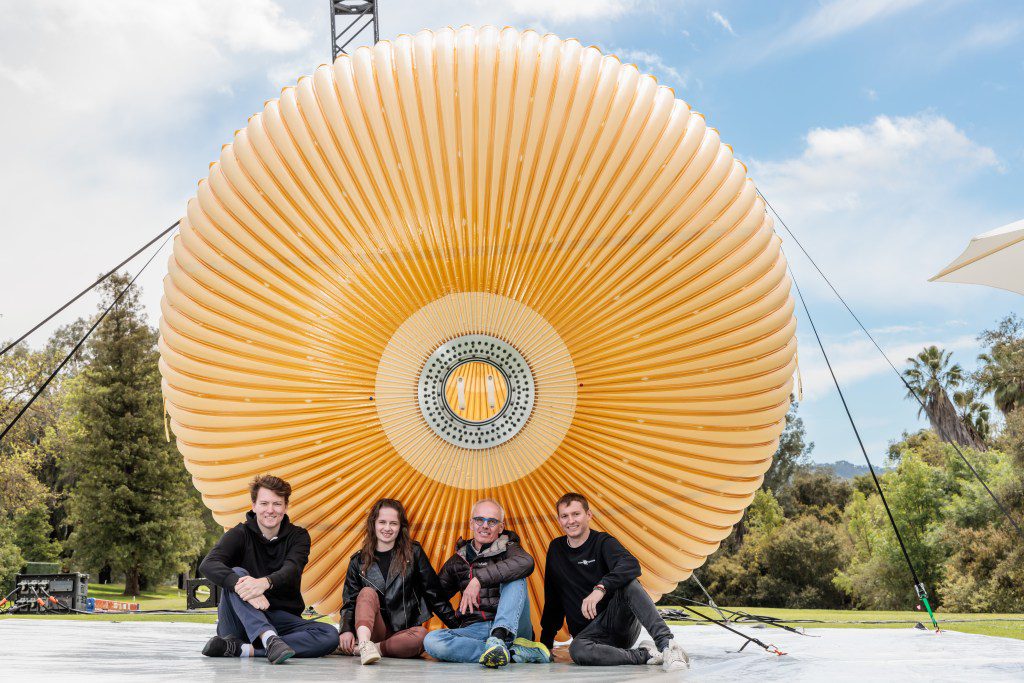

The company has constructed a version of the Max Space 20 module for testing, showcasing it at the invitation-only MARS Conference hosted by Amazon founder Jeff Bezos. The company is currently working on a flight version with improvements such as debris shielding.

The ability to change in size that this design offers will let Max Space to quickly move to bigger units with volumes of 100 to 1,000 cubic meters — the latter the approximate volume of the entire ISS — later this decade. “Our big, exciting goal is…to launch the space station’s equivalent of volume in one Falcon launch,” Kemmer said, with such a module costing as little as $200 million.

A clear use of such units would be for future commercial space stations. “Building space station modules is hard and expensive, and a limiter to a lot of the interesting space applications like in-space manufacturing, biosciences and pharma,” he said. “What we want to do is demonstrate you can do it cheaply.

The company’s first units, though, could be used for other purposes. Kemmer said the initial customers for the units likely will be government agencies interested in using the units as in-space propellant depots or other storage. “It’s definitely not our approach to rush in and put humans up in the first one.

Max Space has no plans to construct its own station, but instead be a provider to other companies developing commercial space stations, such as through NASA’s Commercial Low Earth Orbit development, or CLD, program. “We look at our path to success as working with most other CLD companies and module providers,” he said.

That emphasis on developing the unit technology extends to contracting out elements like the bus that provides power and propulsion as well as life support systems. “We’re focused on our core tech and building that out,” he said.

The company has raised what Kemmer described as a “sub-$10 million” seed round that is funding development of the initial Max Space 20 module and its rideshare launch. The company has less than a dozen employees and doesn’t expect to grow significantly until after the launch of that first module. “Part of our approach is to demonstrate it cheaply and with a small team on purpose,” he said.

Doing so, the Max Space founders argue, will allow them to scale up both the company and the units incrementally. “We have a really good shot of making this happen,” de Jong said, “taking it one step at a time.