Because more and more people are concerned about environmental issues, plastic has become the opposite of sustainability. This is mostly a good thing. But whether you hate it or love it, many plastic products are essential to modern life despite being harmful to the environment. plastic products are here to stay for the simple reason that plastic is as crucial to modern life as it is a bane to the environment.

However, many plastic products are slowly but surely being phased out where possible. Most people are familiar with replacements and even outright bans for single-use products, such as plastic and polystyrene food and beverage containers, bottles, straws, cups, cutlery, and disposable bags. Now, researchers are looking to tackle a plastic-rich industry that has been frustratingly difficult to upend: sanitary products.

Antonio Capezza, a researcher in the polymeric materials division at the KTH Royal Institute of Technology in Sweden, has found a way to replace various polymer fibers in diapers and sanitary pads with porous materials made of biomass waste. That’s protein from the waste of the food and agricultural industries that would have otherwise been discarded, closing the sustainable loop with a neat bow.

“Today, we have many options to avoid plastics in disposable products, but not sanitary products. I love the high tech involved in sanitary products and how much they help families worldwide. Hence, I believe it is time to put time and effort into trying to reduce our environmental impact with these products by providing alternatives and research towards a sustainable sanitary industry,” Capezza told ZME Science.

From accidental discovery to circular innovation

Both tampons and pads have vastly improved many women’s experience with their periods. Pads often contain polyethylene plastic in their back layer for leak protection, while their absorbent core can include superabsorbent polymers (SAPs) that efficiently capture and retain moisture.

Diapers are also incredibly heavy on plastic. The outer layer of most disposable diapers is made of a waterproof plastic material, often polyethylene film, which prevents leaks. The inner layer that sits against the baby’s skin is typically made from a nonwoven, polypropylene fabric designed to be soft and to wick moisture away into the absorbent core, which in turn is made of SAPs.

Unlike single-use plastics, banning plastic in these products has proven unfeasible. They’re just too good at their job and similarly efficient alternatives are lacking. While there is a growing trend calling for reusable diapers and pads, most people would rather not go this route. Can you blame them?

This is why this new research is so promising. And it gets double points for being a happy accident. One day, Capezza was breaking stuff on purpose to teach students what could go wrong in the lab. In one instance, he introduced unwanted humidity while making bioplastic filaments from proteins. The wet cotton he used caused the mixture to foam. Later, when the product dried, he realized that the material was super porous, capable of soaking up a lot of liquid like a sponge.

Similar performance

This lucky moment led to a new area of study. Instead of cotton, which requires bleaching and other chemical treatments to be useful in feminine hygiene products, the researchers turned to natural molecules remaining from food and agriculture. Things like zein from corn, gluten from wheat, and natural antioxidant extracts.

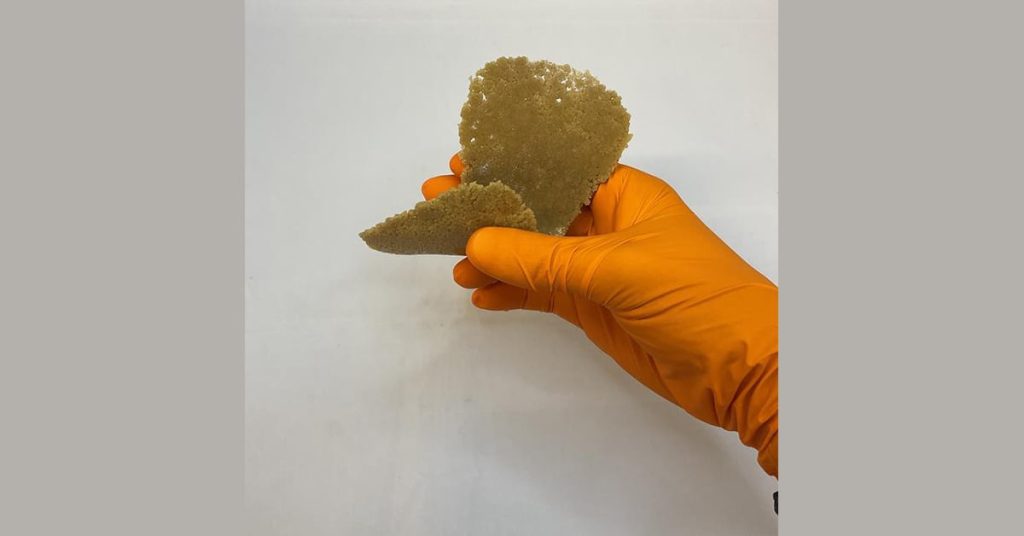

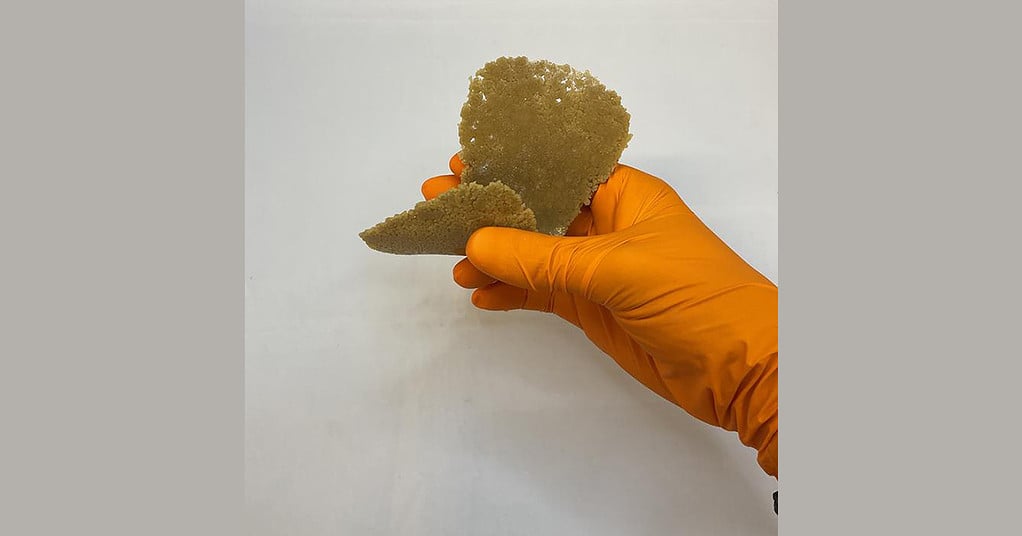

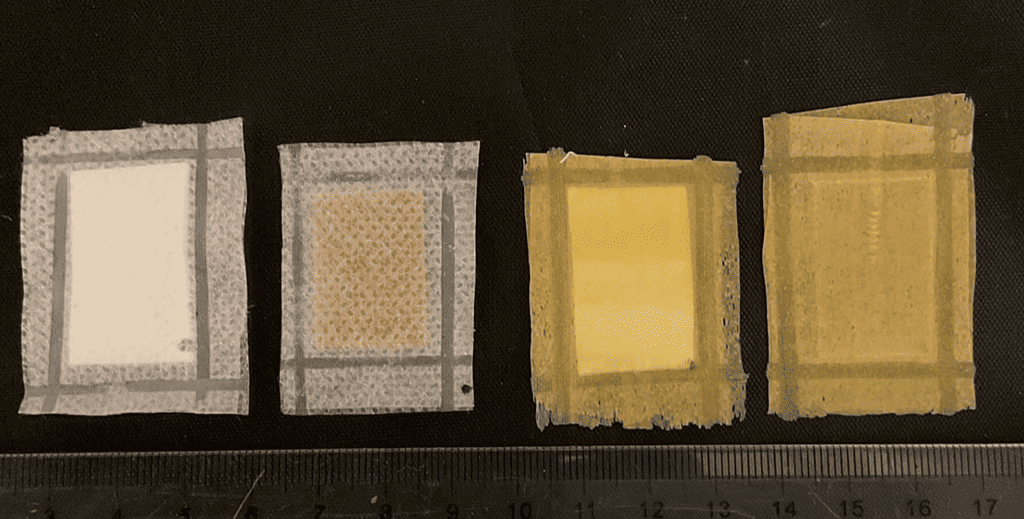

The researchers mixed proteins in different proportions and added water and bicarbonates like baking soda as foaming agents, glycerol as a sweetener to act as a plasticizer, and natural extracts for preservation. They then used plastic industry methods and equipment, such as extrusion similar to a pasta maker, to produce components typical in pads and diapers. This process allowed them to produce both foamed filaments and flat sheets. Using these methods, they created a dry-to-the-touch “nonwoven” layer that allows liquid to pass through quickly, a fluffy porous material that absorbed liquid efficiently, and waterproof films to protect outer garments.

To demonstrate, the team assembled these components into prototype absorbent products resembling disposable feminine hygiene items.

“We are at the same performance level as foams used in feminine pads but below absorbents in diapers. Our research now focuses on increasing the absorption of the materials so they can reach the performance of diapers, which is the other big market for these products. We can reach the performance of diapers if we add more material than today, but of course, this may not be the ultimate solution, as we need future products to be comfortable also for babies,” said Capezza.

A path to sustainability

When exposed to water or soil, these materials decompose within weeks, releasing nutrients like carbon, nitrogen, phosphorus, and amino acids. This compost could then fertilize crops, providing a source for new feminine hygiene products and achieving a completely circular design. Early results indicate that this compost promotes the growth of crops with longer leaves and roots. All this is without the risk of soil contamination with microplastics or harmful chemicals.

“The decomposition test doesn’t guarantee anything about the byproducts itself. However, we have conducted what we call “bioassimilation and leachate” tests, which assess what byproducts we get and whether these are harmful to the environment. Both tests have shown that nothing other than safe molecules for the environment are released (amino acids, nitrogen, carbon),” said Capezza.

Capezza devoted significant time and resources to making the protein-based pads and diapers white, a color that he thought would be more appealing to consumers. “Many people approached me saying that they wouldn’t care about yellow/beige colors as long as they gained sustainability,” he said.

The researchers estimate that these protein-based products might cost 10 to 20 percent more than traditional plastic products. However, the additional cost may be worth every penny for environmentally-conscious consumers. The team is now focused on testing new processes to assess the feasibility of production at scale.

“People should remember that just because something can be broken down by natural processes doesn't mean it's helpful for the environment. We should understand what we are purchasing and the challenges it presents for us and the environment. Sustainability involves not only using natural materials, but also figuring out how to recycle and make sure that the materials we use to make a product come from waste of other industries,” Capezza said.

The results were shared at the current spring meeting of the American Chemical Society (ACS).

Was this helpful?

Related Posts

- Scientists combine spider silk with graphene, create incredibly powerful web

- Physicists measure quantum entanglement in chemical reactions

- ‘Extinction: The Facts’: Attenborough’s new documentary is surprisingly radical

- Scientists find new species of wood-munching, phallic-shaped clams