Many people at the grocery store don't think about how much effort goes into getting a sweet potato from the ground to the shopping cart. Sweet potatoes come in different sizes and flavors, but consumers expect them to be consistent. To meet this demand, sweet potatoes go through time-consuming quality checks to get rid of batches that are too firm, not sweet enough, or unlikely to sell. This is currently done by humans in a lab, but a new study suggests that hyperspectral cameras and AI could speed up this process.

In a study published this week in Computers and Electronics in Agriculture, researchers from the University of Illinois wanted to see if data collected by a hyperspectral imaging camera could help identify certain potato attributes that are usually determined by manual inspectors and tests. Hyperspectral cameras gather a lot of data across the electromagnetic spectrum and are often used to figure out the chemical makeup of materials. In this case, the researchers aimed to analyze data from potato images to accurately determine a spud’s firmness, soluble solid content, and dry matter content—three key attributes that affect the vegetable’s taste and market appeal. Normally, this process involves testing like leaving potatoes in a 103 degrees celsius oven for 24 hours.

“Traditionally, quality assessment is done using laboratory analytical methods,” University of Illinois College of Agricultural, Consumer and Environmental Sciences assistant professor Mohammed Kamruzzaman said in a statement. “You need different instruments to measure different attributes in the lab and you need to wait for the results.”

The researchers took photos of 141 defect-free sweet potatoes from multiple angles. Hyperspectral imaging produces a lot of data, which can be a challenge for researchers looking for specific variables. To address this, the researchers used an AI model to filter the noisy data into several wavelengths. Then, they connected those wavelengths to the specific desirable sweet potato attributes they were looking for.

“With hyperspectral imaging, you can measure several parameters simultaneously. You can assess every potato in a batch, not just a few samples,” Kamruzzaman added.

AI and hyperspectral cameras could speed up vegetable inspection

The researchers suggest that farmers and food inspectors could use hyperspectral imaging and AI to accurately and cost-effectively scan sweet potatoes for key attributes while reducing food waste created by traditional testing methods. While this study focused on sweet potatoes, similar tactics could be used to find desired features in other vegetables and fruits. Kamruzzaman and his colleagues hope to develop a way to quickly and easily scan sweet potato batches. On the consumer side, the researchers imagine creating an app for grocery store patrons to scan a potato and look up its attributes. This app could potentially reduce patrons awkwardly handling their produce.

“We think this is a new use of this method for evaluating sweet potatoes,” Toukir Ahmed, a doctoral student and the main author of the study, wrote. “This groundbreaking work has the potential to open up the possibility of using it in a wide variety of other agricultural and biological research areas as well.”

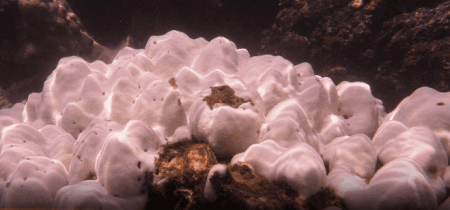

The farming industry is increasingly relying on AI solutions . They are doing this in order to increase efficiency and prevent growing shortages of farm labor. From self-operating machines that check tulips in Holland to independent tractors made by John Deere to , farmers around the globe are hoping that these new advancements can eventually decrease food prices and improve their own profitability. However, it is still uncertain how everything will unfold. The benefits to agriculture from AI solutions may also take longer to help economically developing countries,where some farming is still done manually. Produce was sorted using hyperspectral imaging.