I was writing a while ago that major biofuel production is not really that far away and the good news is things seem to be moving in that direction. The importance of biofuels has been underlined as a possible solution to fight the crisis, but the big problem was that creating such alternative fuels required too big amounts of power, despite numerous options that were considered (sugar, waste materials and even algae).

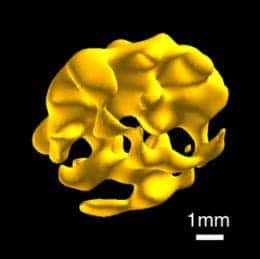

The invention is basically a bioreactor that creates microbubbles using 18% less energy. Microbubbles are miniature gas bubbles (measuring less than 50 microns in diameter) which means they can transfer materials in a bioreactor much more faster than with regular bubbles, thus using less energy. This innovative approach has the whole scientific world excited and it’s currently being tested with a local water company, and it’s also estimated that the necessary electricity current will be 30% lower;we will post updates as they are released by the researchers.

Professor Will Zimmerman, from the Department of Chemical and Process Engineering at the University of Sheffield, said: “I am delighted that our team’s work in energy efficient microbubble generation is being recognized by the Institution of Chemical Engineers. The potential for large energy savings with our microbubble generation approach is huge. I hope the award draws more industry attention to our work, particularly in commodity chemicals production for gas dissolution and stripping, where energy savings could enhance profitability. There are many routes to becoming green, and reducing energy consumption with the same or better performance must be the most painless.”

Professor Martin Tillotson, from Yorkshire Water, added: “Many of our processes use forced air in order to treat water and wastewater streams and, given the huge volumes, it is very costly in electricity and carbon terms. This technology offers the potential to produce a step-change in energy performance. We are pleased to be working with Professor Zimmerman and his group in developing the microbubble technology, and delighted with the recognition they have received from the Moulton Medal award.”